The only constant that I cannot overcome is the time for glue to dry; while other, faster setting product are available, the ability to "undo" with a little water makes the waiting worthwhile.

Sunday Surge of Activity

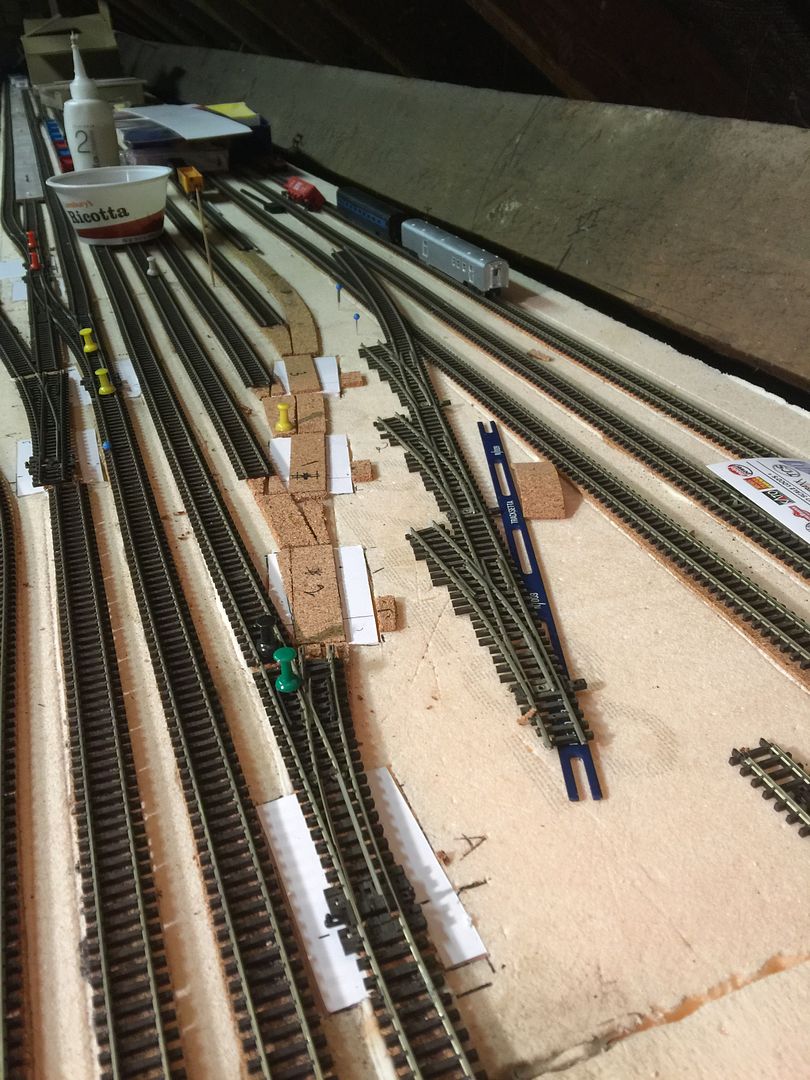

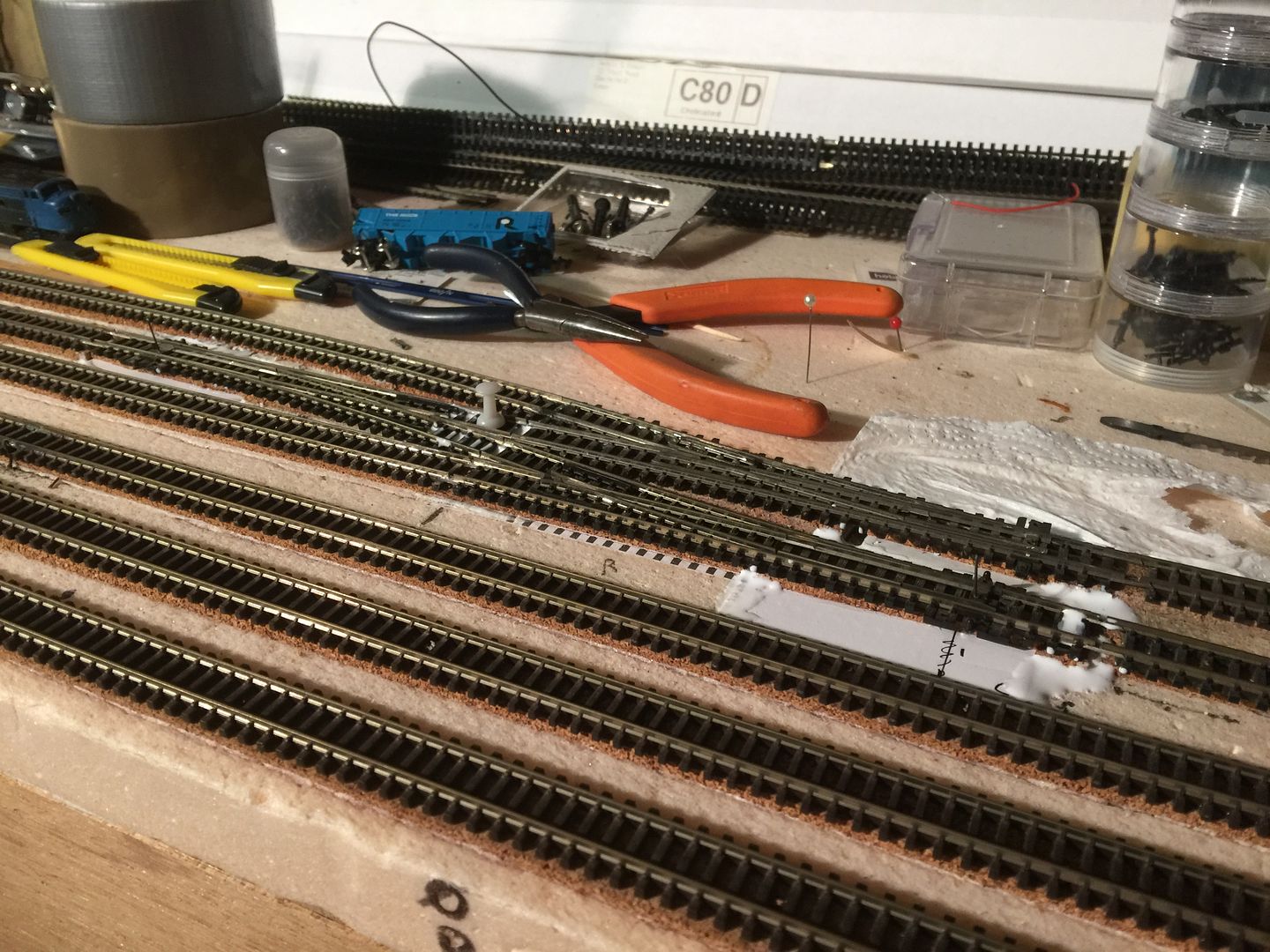

I prepared eight points for servo installation over the course of a few hours on Sunday, while literally waiting for paint to dry on a domestic project.

I also hung four doors, and installed a bathroom cabinet, but that is another project, and as there are no pictures, you will have to take my word for it.

In addition to this work I managed to run a train, briefly, as since most of the servo installation has mean a cut main line, I have not had much opportunity lately.

Sunday Surge of Activity - Second Part

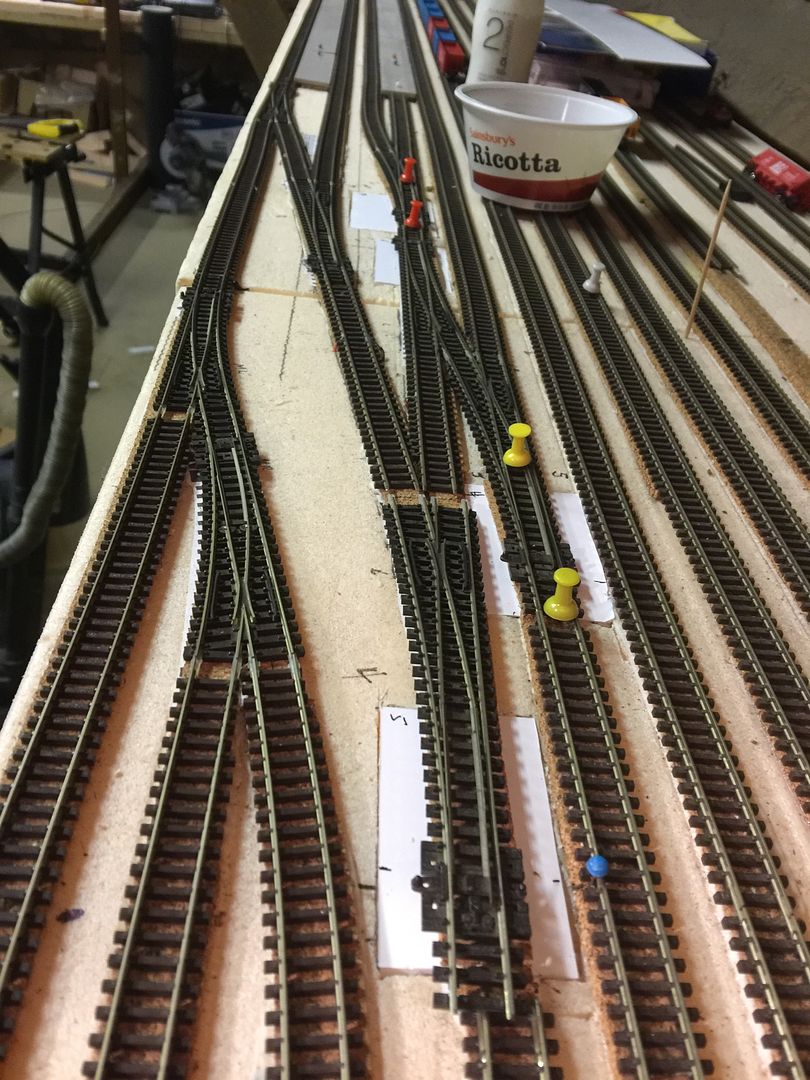

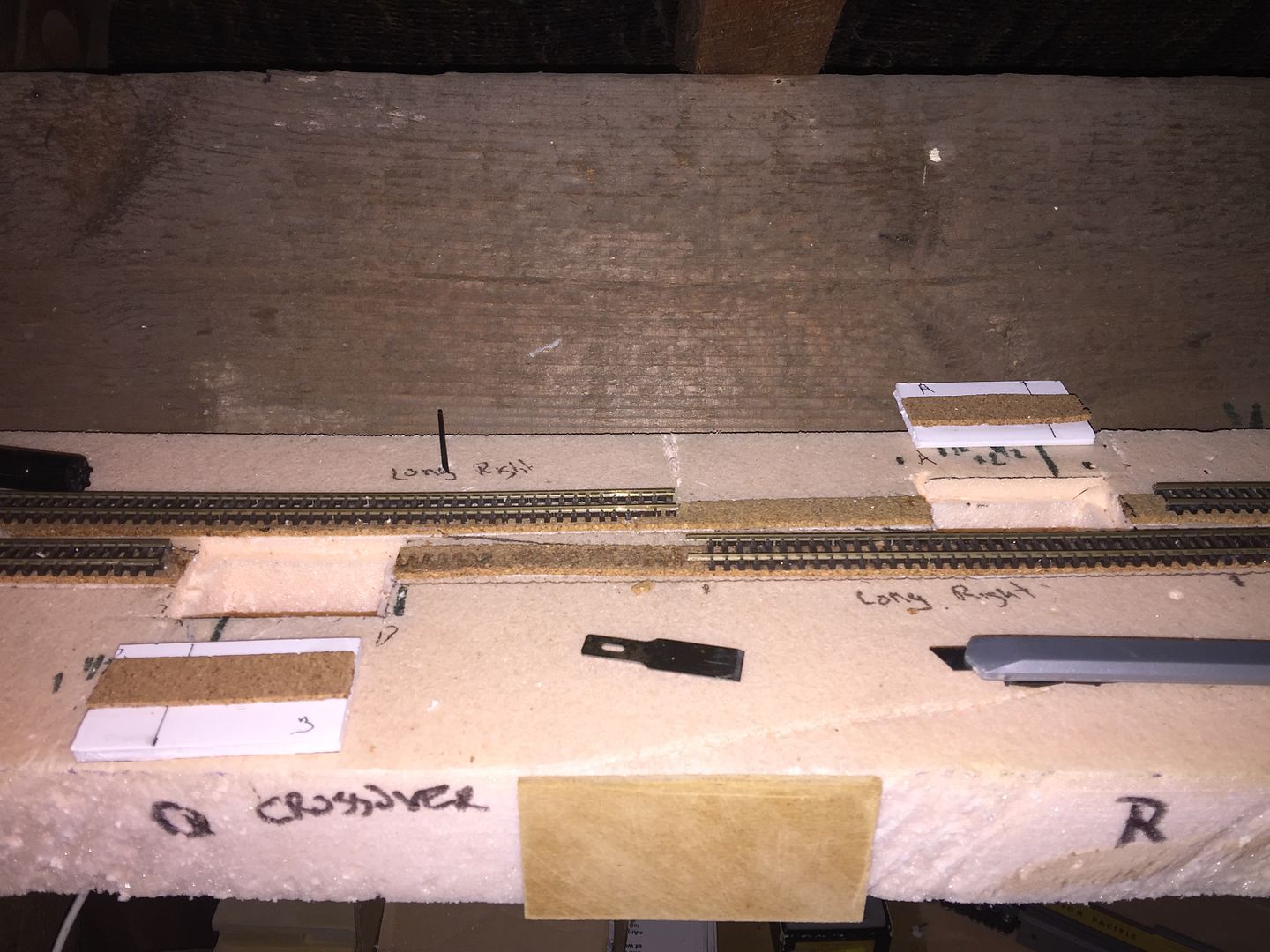

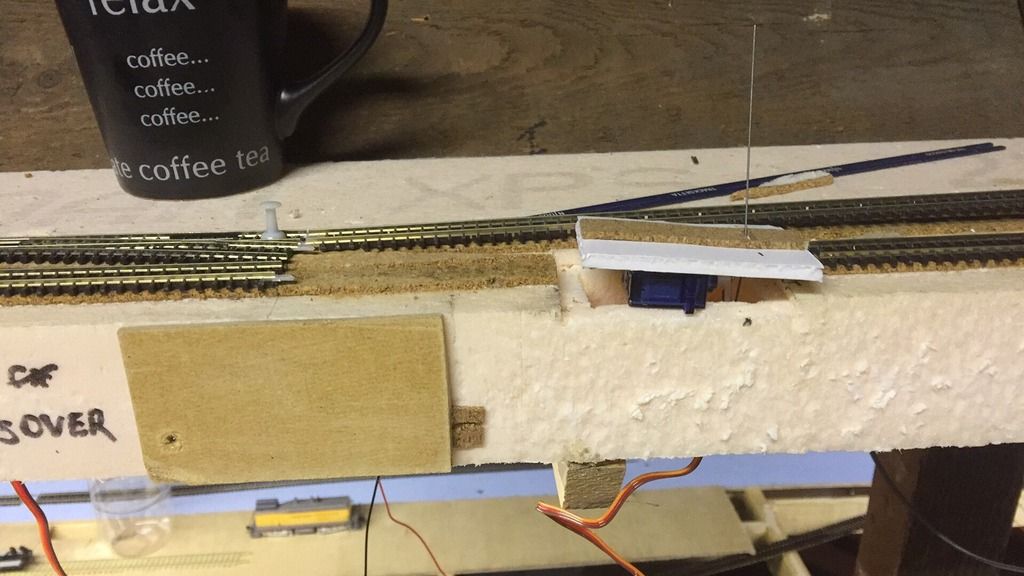

In addition to the yard ladder, I prepared these four turnouts on the station approach tracks. This entailed removing the last of the Peco twin-coil motors, as seen by the larger footprint of the mounting pad in the top of the picture, between the red push pins.

All boards are fitted in the cut holes while the last of the glue sets on the cork, so I can whisk through mounting the servos on the next visit.

The next group will be the four on the left-hand side of the picture; the two in the coach yard, the platform 1 and 2 turnout, and one at the top edge, that allows access from platform 1 to the coach tracks.