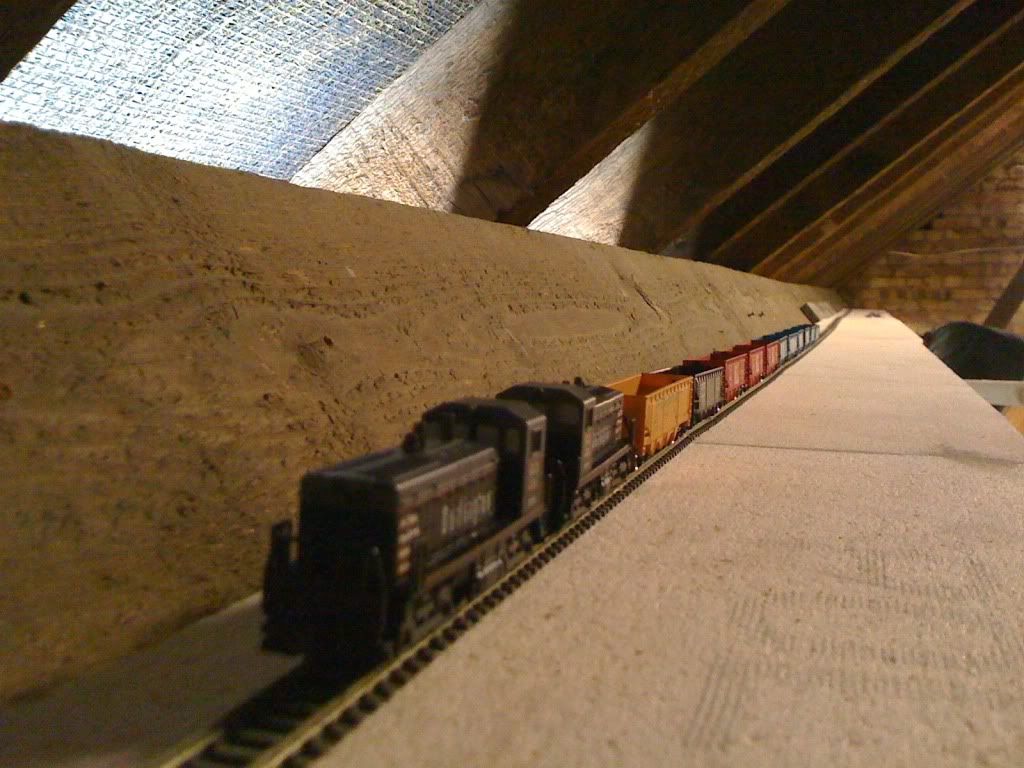

Over the weekend I laid another twenty-some feet of track. And test ran a train. Unfortunately I ddin't have the video camera with me, so you will have to wait.

One thing I did learn: with approximately fifty feet of run, it was possible to run the train from a single set of feeders, positioned at about the twenty/thirty feet marker. None of the other joiners were soldered, apart from where the feeders were attached. After cleaning the track (and removing up to twenty year's worth of grime!) the train ran wonderfully, all the way to the last section in one direction...

Does this constitute a plan for the future? Heck no!

- Every-other joint will be soldered

- Feeders WILL be included in every soldered joint (max run six feet per feeder, centered).

- I need a whole lot of no-ox...

More to follow!

And from now on, being as I have caught up, posts will represent current progress