I added the servo motors to control the crossover near the

site of the freight siding.

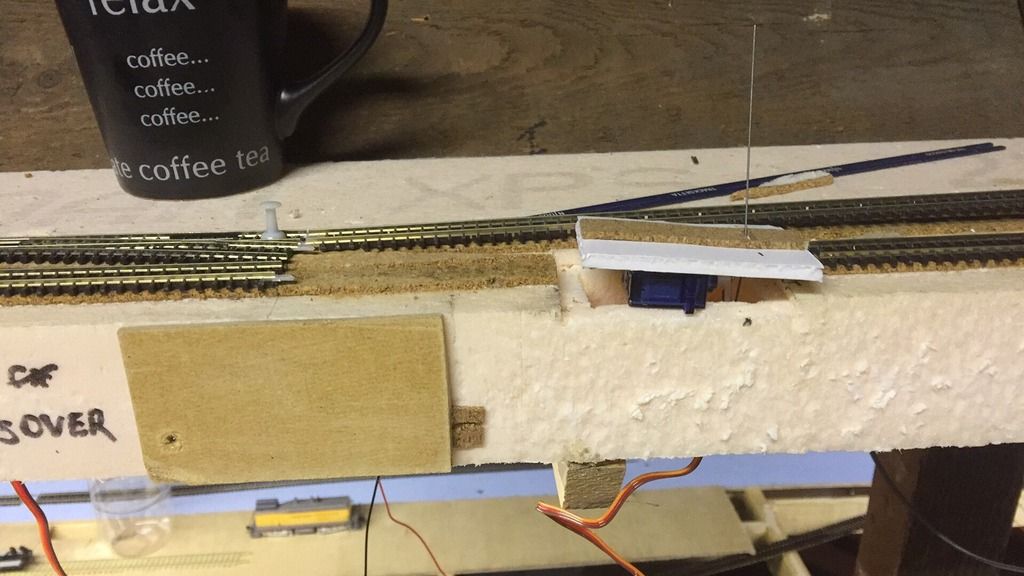

Servo Motor Installation Example

One placed on second crossover, second in progress. You can

see how the servo motor is mounted, and how this will throw the turnout once

the track is placed.

Crossover and Freight Spur Complete

Crossover in place, motors tested, surrounding track glued

in place. Won't get time to re-wire (short section between crossover and spur

has no power yet) so run testing will have to wait. Just need to power the spur

and the section of track immediately before it, as the original block has been

split. The section of mainline will allow small amounts of switching without

fouling the mainline crossover.

With this complete I left the glue to dry (resisting the

temptation to mess with it) and moved down the mainline the next crossover,

going the opposite direction.

Powering Another Crossover

And on to the next crossover to get powered; you can see the

tools I use to cut the foam, the servo mounting pads, and the gaps where the

turnouts should be...

Opening the Mounting Pad Locations

Cuts made for the mounting pads; the combination of a saw

and sharp knife does wonders.

The Hole Detail

Detail of the hole for the mounting pad; you can see the lip

that supports the foam core board.

Roadbed Restored

Roadbed splices cut and glued. This cork sheet cut into

strips approximately as wide as the track ties.

By this point Imogen (the British have started naming winter

storms…) was putting too much cold wind through the attic, so I retreated

downstairs, since the glue was taking longer to dry. Hopefully in a couple of

weeks I’ll get this and the maybe even the next one done.